Subsurface Multiphase Pumps (Artificial Lift)

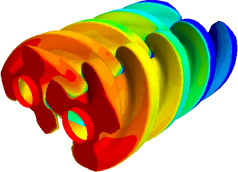

Thermal Testing with Solids

A new patented technology was born after extensive research & development. The ESTSP (Electric Submersible Twin Screw Pumps)-Multiphase is available for world wide applications. It is expected to capture 15 to 20% of the artificial lift market within 7 years. This is our set target. Several areas of the pump have been patented and some are patent pending.

Models:

In our standard manufacturing range:

CE & ATEX certified for Europe- ESTSP 425

- ESTSP 540

- ESTSP 675

Custom Made Designs as per requirements for various casing sizes to maximize productivity.

- ESTSP 272

- ESTSP 370

- ESTSP 400

- ESTSP 513

- ESTSP 540 Max*

- ESTSP 425 Max*

* Max is the same type of pump as within our standard manufacturing range but with extra rates for the same differential pressure for the same diameters.

- Minimum Rates: 50 bbl/day (equivalent fluid-reported at intake conditions)

- Maximum rates: 17,000 bbl/day (equivalent fluid-reported at intake conditions)

- Maximum Differential Pressure: 3500 psi

- Minimum Intake Pressure: 0 psig to (-10 inches of Hg) vacuum conditions

- Suitable with any ESP motor and all accessories

- Pump is designed up to 350°C ambient but limited by the motor temperature capability which will limit to 250°C ambient.

ESTSP would mean Electric Submersible Twin Screw Pump and for eg: 425 would mean 4.25 inches outer diameter.

- Casing suitability of 4 1/2 inch casing or larger

- Can be landed vertical, slanted or horizontal

ESTSP - Electric Submersible Twin Screw Pumps

ESTSP (Electric Submersible Twin Screw Pumps)-Multiphase, is a Paradigm change in Artificial Lift Technology

Wear Resistant Coatings (Hardness 3800 Knoop)

- Move all fluid up the tubing including all gas complete. True Multiphase Pump. - OPEX savings

- Isolate casings if required. Throw away gas lines from the casing to pull out gas. Use inexpensive casings for new wells in high H2S wells. -OPEX and CAPEX savings

- By moving all gas up the tubing you will reduce head requirement (lower fluid density), increase life of the motor, and have more hp to move fluid. - OPEX and CAPEX savings

- You don’t need any surface multiphase pump as you can use the ESTSP to move the complete fluid all the way to the battery as the ESTSP is a Multiphase Pump. Handle Gas in a compressed state downhole without any separation. - OPEX and CAPEX savings

- Reduce foot print on offshore platform.

- You will see the motor will cool faster and temperature rise is minimal even with high gas due to “dew point effect” that happens when you move fluid up the tubing swiftly. - OPEX and CAPEX savings

- Use one model pump for the entire life of the well and the field in some cases until abandonment. - OPEX savings

- It has the least shear compared to any other pump so it has very little emulsion. Save on de-emulsifiers. - OPEX savings

- Asphaltene will not break out easily due to very low shear.

- Control the pump with one parameter and that is the speed. Though unheard of in the ESP industry it is common to run from 25 to 90 HZ. The pump is balanced and all the thrust is shared between two shafts within the pump increasing life of the pump. No buckling of shafts.

- Use it for heavy oil, light oil and high gas. Multiphase.

- There is no need to do any throttling. There is no BEP. There is NO up or down thrust.

- It is installed exactly like an ESP. There is nothing new to learn. Just install, set it to low torque and high torque and walk away. All existing accessories of ESP can be used for ESTSP.

- Draw down to 0 psig or to vacuum at Intake. No other artificial lift can sustain such a performance.

- It is Operator Proof.

Thermal Gradient Under Thermal Application

Request publications and brochures under Contact Us

Perfect Axial Flow (Very Low Shear and Minimal Emulsion)